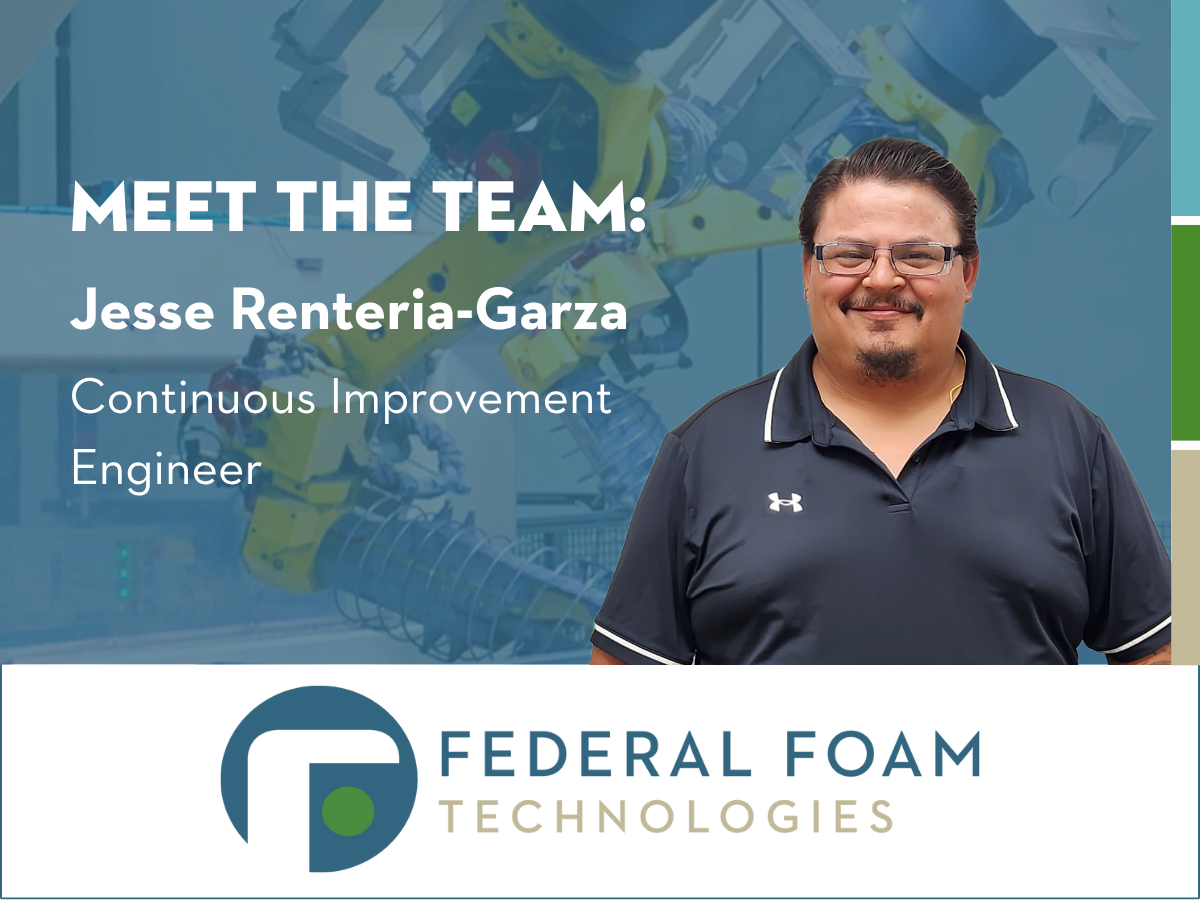

At Federal Foam Technologies, we take pride in spotlighting the people who shape our culture and drive our success. In this spotlight, we highlight Jesse Renteria-Garza, a valued team member whose commitment and contributions have created significant improvements within our organization.

Meet Jesse Renteria-Garza

Jesse began his career with ACT and officially became part of the Federal Foam family in 2015 when the company acquired ACT. Altogether, he’s been with the organization for about 25 years, a milestone that speaks volumes about his dedication, adaptability and passion for continuous improvement.

Today, Jesse works as a Continuous Improvement Engineer, helping the company operate more efficiently and productively in foam and plastic production processes. While he’s part of the Corporate team, Jesse spends most of his time on the ground at the Northwood, Iowa facility, collaborating directly with teams and supporting process improvements across all three plants.

“I love being hands-on and working with people to solve problems. Every improvement, no matter how small, makes a difference,” Jesse shares.

A Day in the Life of a Continuous Improvement Engineer

One of Jesse’s favorite aspects of his job is working hands-on with production teams to resolve issues and improve operations. He analyzes workflow inefficiencies, identifies root causes and develops practical solutions to streamline processes. Jesse also works directly with his supervisor, Director of Operations Mark Siegfried, to implement changes that drive long-term improvement and uphold high standards of quality and efficiency.

In addition to optimizing performance, Jesse operates the Die Cut, Water-Cut and Thermoforming machines. The variety between the three machines creates a dynamic work day, as each machine requires a different set of skills, attention to detail and problem-solving approaches. Although it’s a tough decision, his favorite machine out of the three is the Thermoforming machine. Working primarily on this machine at the Northwood Plant, Jesse enjoys the hands-on process of thermoforming plastics and takes pride in creating high-quality, precision-formed parts.

While Jesse enjoys the never-ending changes in his day-to-day job, it doesn’t come without its challenges. One such project he recently completed was sourcing a new silicone membrane (otherwise known as a “bladder”) for the production team to use to more accurately form parts. By incorporating these into their workflow, the team can achieve greater consistency in part quality, reduce material waste and improve overall production efficiency.

“It was really rewarding to be able to see the team work with these new membranes,” Jesse states. “It was great to be able to find a solution to make the process easier.”

Hobbies Outside of Work

Although he’s known as FFT’s Continuous Improvement Engineer at work, outside the office he’s better known as Coach Jesse. In his free time, he coaches a local travel baseball team, as well as basketball, football and the high school baseball team.

When he’s not coaching his teams, Jesse enjoys spending time with his family.

“My family is absolutely amazing at handling my work and coaching schedule,” Jesse says. “I appreciate everything they’ve done for me.”

A Journey of Personal Growth

Recently, Jesse embarked on another important journey: becoming a U.S. citizen. While he describes the naturalization process as a bit nerve-racking, he also says it went smoothly thanks to the encouragement he received from leadership.

“Mark was one of my biggest supporters from the beginning,” Jesse said. “Wyman Smith and Melanie Rowe were always willing to help, too. If I needed time off for appointments or just had questions, they were understanding and there for me.”

While the decision to move forward with naturalization was Jesse’s, the support he received from the company helped make the transition feel easier. From flexibility in scheduling to genuine encouragement, Jesse felt empowered every step of the way.

When asked what advice he’d give to someone going through a similar experience, Jesse offered a message of hope and honesty.

“Be patient and trust that anything is possible. Honesty is the key to success.”

Want to join FFT?

For those looking to join the Federal Foam team, Jesse had this to say.

“Be ready to bring your ideas to the table. This is a place that values innovation, teamwork and a mindset for continuous improvement. If you’re driven to make things better and want to be part of a supportive, forward-thinking environment, this is the place for you.”

For more information on our career opportunities, click here.