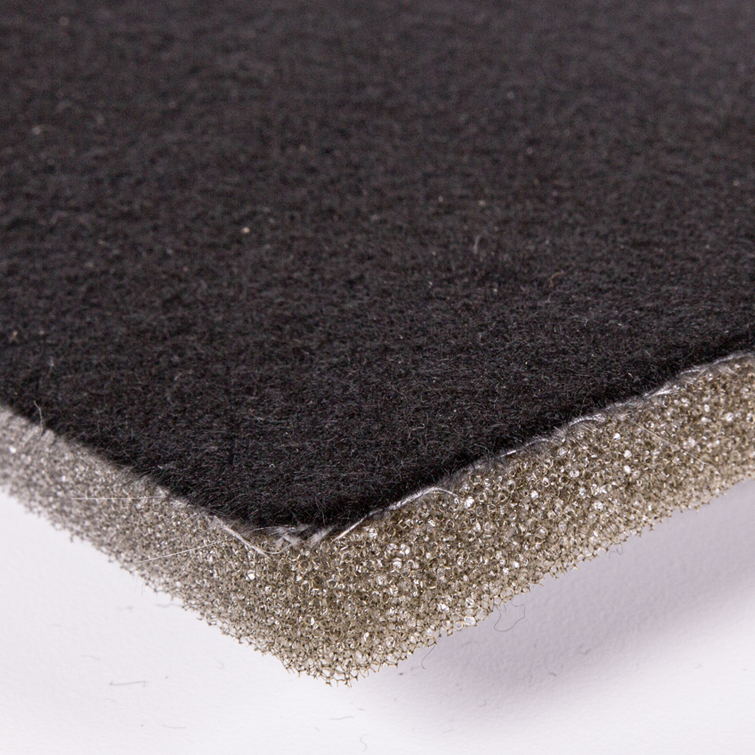

Composite

![]()

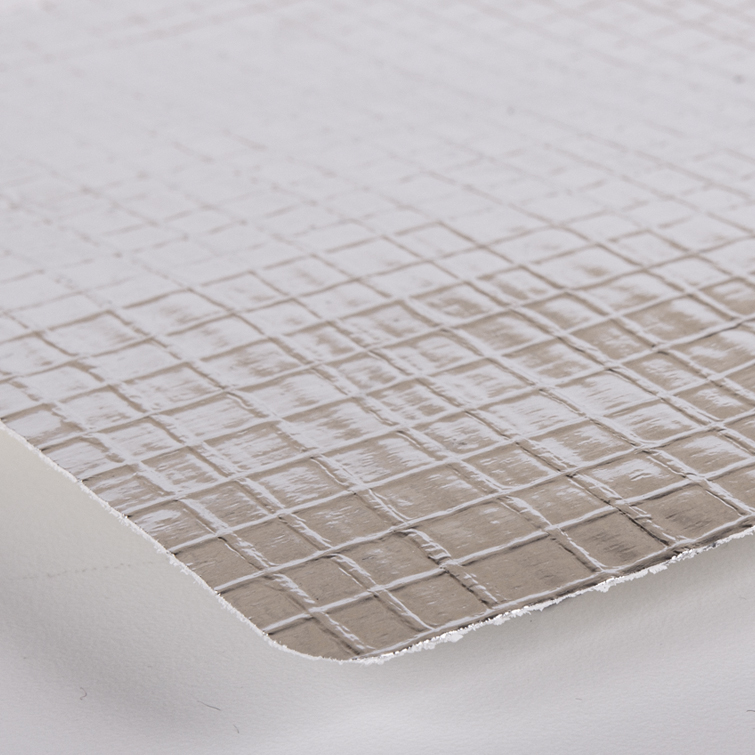

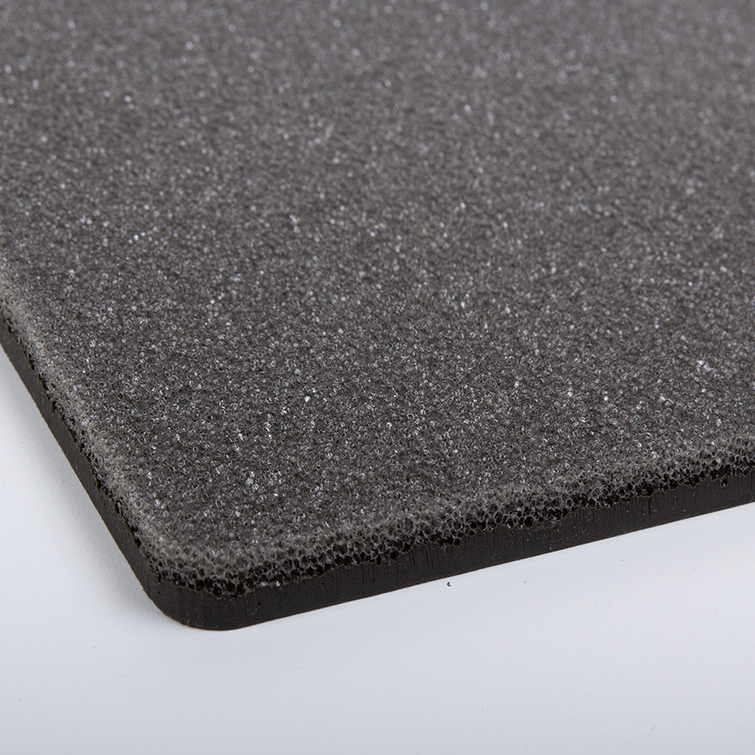

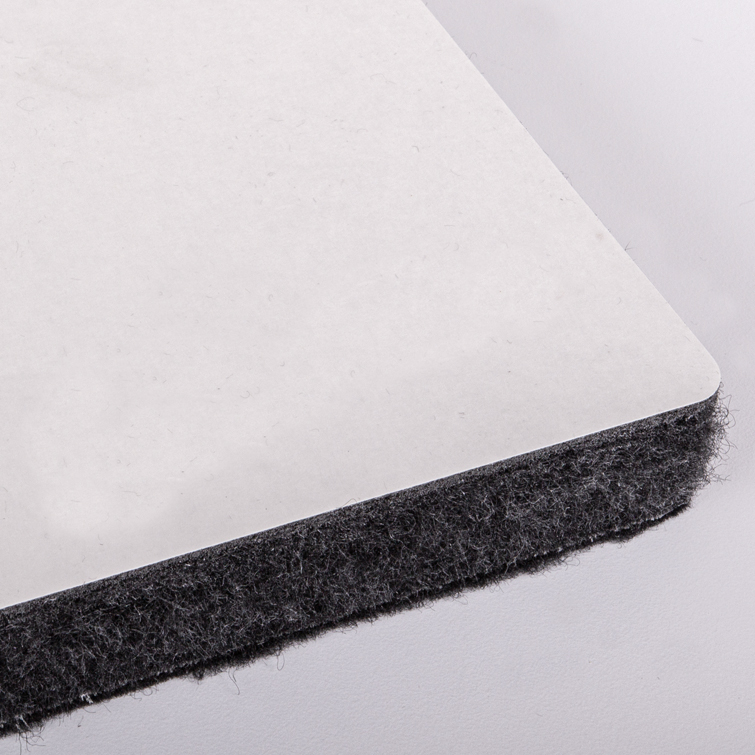

Solid Sound Transmission Barrier

Material # 11100

Product summary:

11100 is used as a sound transmission barrier for blocking airborne sound and as a vibration damper for reducing noise generated from vibrating surfaces. The physical properties of this material make it ideally suited for electronic equipment and computers; copiers and office equipment; engine and machine enclosures; room enclosure panels; refrigeration; heating; air conditioning equipment; home appliances and many others.

Weight : 1 ± 0.1 lbs. / ft.²

Recommended Temperature Range : -20°F to 160°F

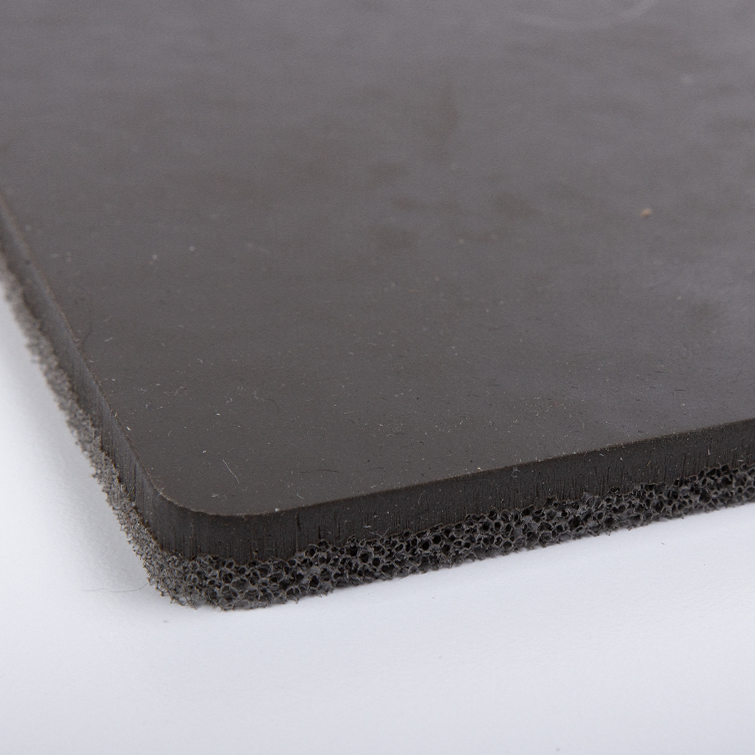

Filled Plastisol Barrier

Material # 11200

Product summary:

11200 is used as a sound transmission barrier for blocking airborne sound and as a vibration damper for reducing noise generated from vibrating surfaces. Once cured, the material is very limp and flexible.

Pattern Embossed Floormat/Accoustical Barrier

Material # 90425

Product summary:

90425 is primarily used as an acoustical noise barrier in off-highway transportation markets. Its toughness and surface finish make it ideal for wear surface/floor mat applications. The high basis weight helps block sound and allows it to act as a mass damper to attenuate structure-borne noise.

Flammability : Certified

![]()

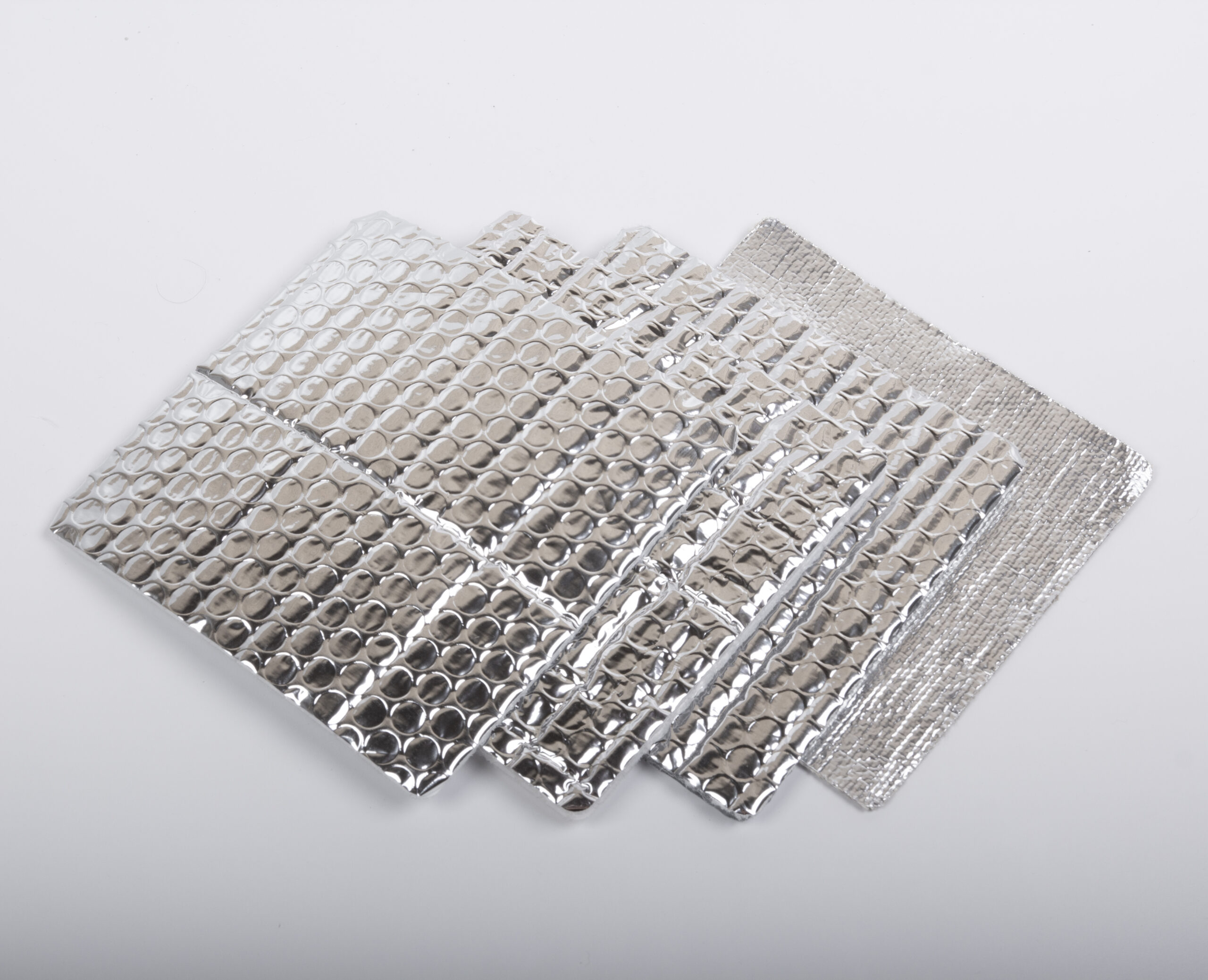

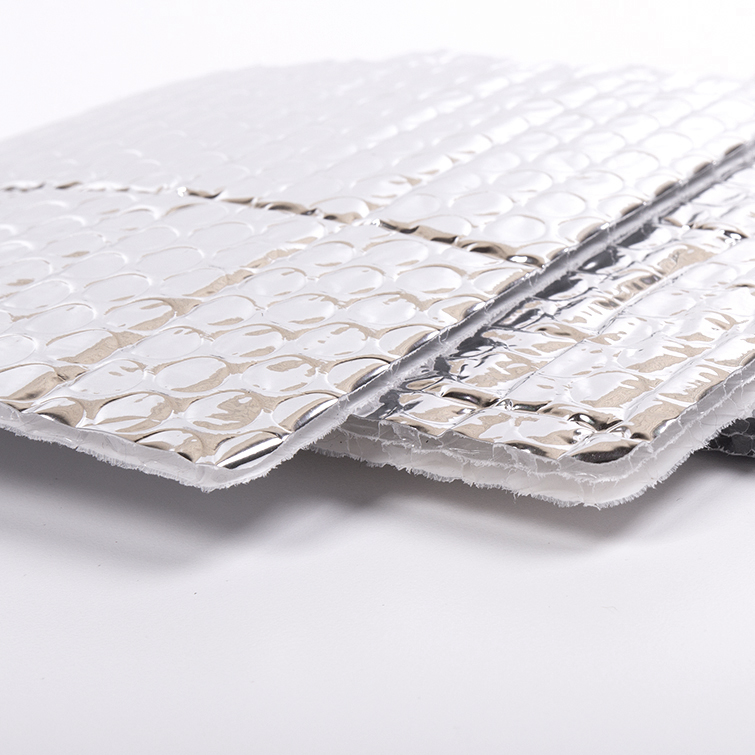

Reflective Bubble Foil / Insulation - SBW

Material # 12500

Product summary:

12500 is a multi-layer aluminized polyester-faced radiant heat/vapor barrier. This material utilizes the low emissivity properties of aluminum to greatly reduce heat radiated by troublesome heat sources. A single layer of polyethylene bubble pack acts as an isolator between high emissivity materials and the aluminum to enhance its low emissivity properties. Applications include: appliance manufacture, recreational vehicles, automotive, off-road equipment, generators, buildings, and many other enclosures.

Water Absorption / Water Repellancy : Water Vapor Permeability - 0.002 Perms Max

Temperature Resistance : "Hot Surface Performance: ASTM C 411 - 96 Hours @250°F, No Damage"

Reflective Bubble Foil / Insulation - DBW

Material # 12501

Product summary:

12501 is a multi-layer aluminized polyester-faced radiant heat/vapor barrier. This material utilizes the low emissivity properties of aluminum to greatly reduce heat radiated by troublesome heat sources. Two layers of polyethylene bubble pack act to isolate high emissivity materials from the aluminum to enhance its low emissivity properties. Applications include appliance manufacture, recreational vehicles, automotive, off-road equipment, generators, buildings, and many other enclosures.

Water Absorption / Water Repellancy : Water Vapor Permeability - 0.002 Perms Max

Temperature Resistance : "Hot Surface Performance: ASTM C 411 - 96 Hours @250°F, No Damage"

Reflective Double Bubble Dual Foil / Insulation

Material # 12502

Product summary:

12502 is a multi-layer aluminized polyester-faced radiant heat/vapor barrier. This material utilizes the low emissivity properties of aluminum to greatly reduce heat radiated by troublesome heat sources. Two layers of polyethylene bubble pack act isolate high emissivity materials from the aluminum to enhance its low emissivity properties. Applications include: appliance manufacture, recreational vehicles, automotive, off-road equipment, generators, buildings, and many other enclosures.

Water Absorption / Water Repellancy : Water Vapor Permeability - 0.002 Perms Max

Temperature Resistance : "Hot Surface Performance: ASTM C 411 - 96 Hours @250°F, No Damage"

Aluminized Fiberglass Cloth

Material # 23500

Product summary:

23500 is a tough, flexible, foil-faced fiberglass cloth. It is used for welding protection, insulation, gaskets, expansion joints, heat shields and containment, oven door seals, emergency fire blanket, tadpole tape, machinery, personnel protection, safety clothing, and more.

Thickness : Foil - 0.001” nominal

Weight : Composite - 21.5 oz. / yd.² (0.729 kg/m²) ±15%

Weight : Base Cloth - 18.0 oz. / yd.² (0.610 kg/m²) ±10%

Temperature Resistance : Cloth - 1000°F (538°C)

Temperature Resistance : Adhesive - 300°F (148°C)

Temperature Resistance : Foil - 1200°F (649°C)

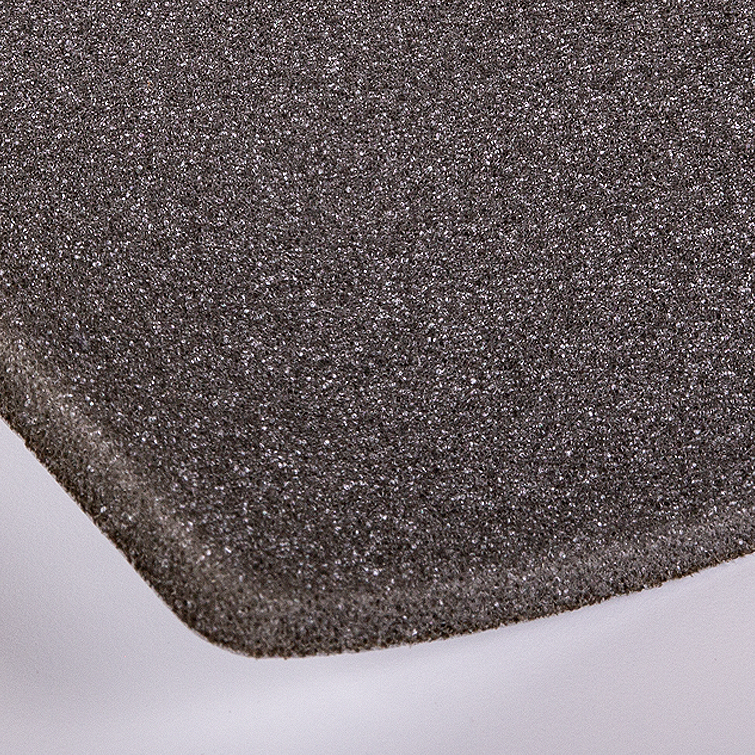

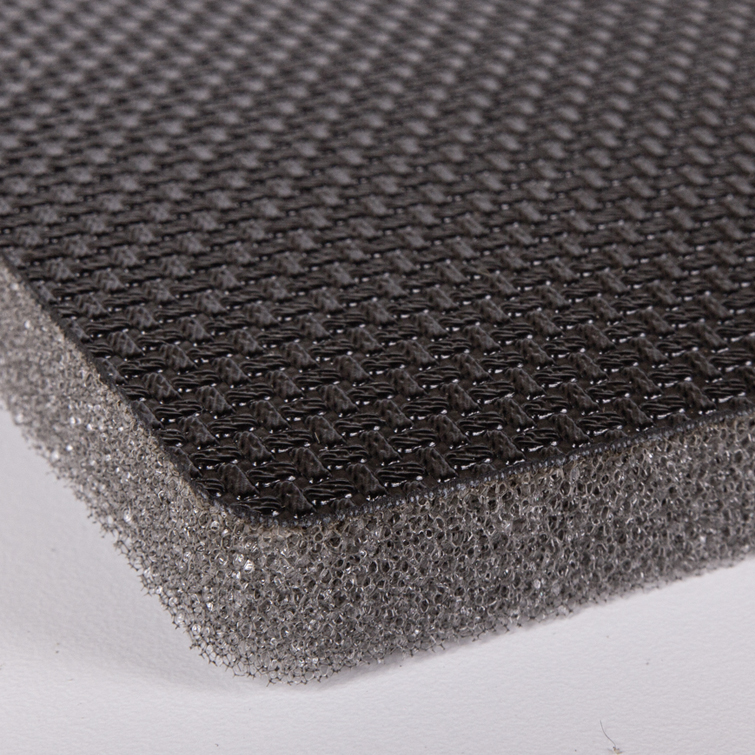

Carbon / Fiberglass Composite Cloth

Material # 23521

Product summary:

23521 is a soft, flexible, high-temperature, and flame-resistant carbon/fiberglass composite cloth. This material can be used as a high-temperature insulator in underhood applications in construction/off-road equipment, ATVs, and snowmobiles. It doubles as a sound absorber to reduce operator ear and drive-by noise levels. Having a soft, black texture gives it conformability and aesthetic qualities not typically correlated with high-temperature materials. It can perform in wet or dry environments, retaining 75% of its strength when wet. As an added bonus, the material is non-irritating, making it easier to work with and install.

Weight : Composite - 14.0 ±2.1 oz. / yd.² (0.475 ±0.071 kg/m²)

Temperature Resistance : Continuous - 500°F (260°C)

Temperature Resistance : Base Fiberglass - 1000°F (538°C)

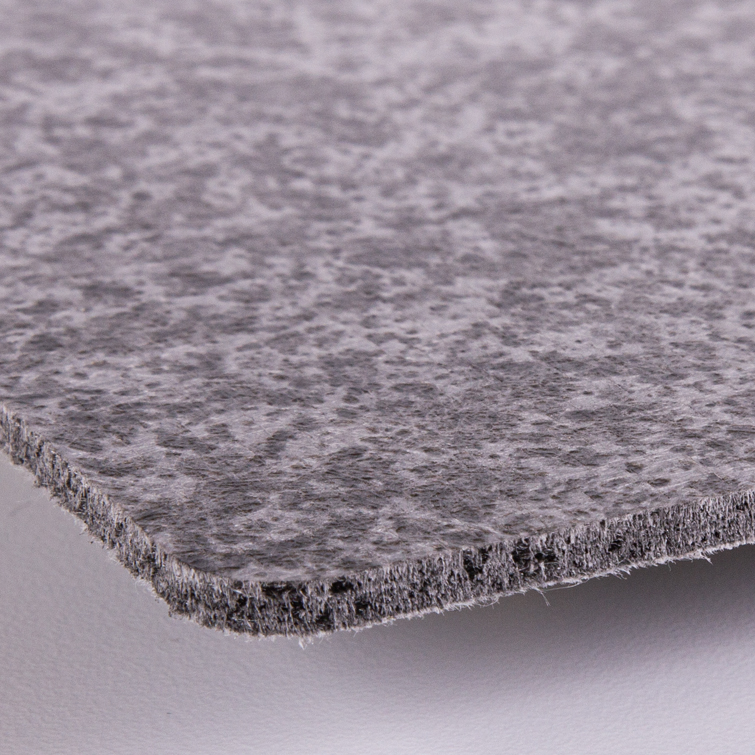

Pre-Ox / Rayon Insulation

Material # 23531

Product summary:

23531 is soft, flexible, high-temperature, and flame-resistant pre-ox/rayon composite felt. This material can be used as a high-temperature insulator in engine compartment applications in construction/off-road equipment, ATVs, and snowmobiles. It insulates and dissipates heat, and can be combined with other materials (foils, pressure sensitive adhesives, foams, etc.) to address specific needs for different applications. The material is non-irritating, making it easier to work with and install.

Weight : Composite - 24 ±1.7 oz. / yd.² (0.756 ±0.058 kg/m²)

Temperature Resistance : Continuous - 500°F (260°C)

Temperature Resistance : Intermittent - 1800°F (982°C)

Silicone Coated Fiberglass Cloth

Material # 23540

Product summary:

This product is used in industrial and off highway insulation composites. Silicone coated glass cloth is typically used as the outside layer of a composite to protect it from water and oil and give added durability.

Weight : Cloth (nominal) - 32 oz. / yd.²

Temperature Resistance : Cloth - 500°F (260°C)

Silica Cloth

Material # 23550

Product summary:

This product is used in industrial and off highway insulation composites. Silica cloth is typically used as the hot side layer of a composite for maximum temperature resistance.

Weight : Cloth (nominal) - 24 oz. / yd.²

Temperature Resistance : Cloth - 1800°F (982°C)

Underhood Nonwoven Fabric

Material # 23565

Product summary:

23565 is a chemically bonded nonwoven fabric. This material is flame retardant, water resistant, and chemical resistant. Primary applications include under hood facings for automotive, construction, and recreational equipment. Its fibrous structure makes it an excellent sound absorber.

Water Absorption / Water Repellancy : Water Repellancy - TP 10.4.2-020 - ≥1 hour

Flammability : FMVSS302 Certified

Fiberglass Insulation Mat

Material # 23570

Product summary:

This product is used in industrial and off highway insulation composites. Fiberglass mats are typically used as primary insulating layers within composites, providing excellent thermal and acoustic properties.

Weight : Nominal - 54.0 oz. / yd.²

Density : @0.482" - 9.37 lbs/ft³

Density : @12.2 mm - 150 kg/m³

Temperature Resistance : Cloth - 1000°F (538°C)

![]()

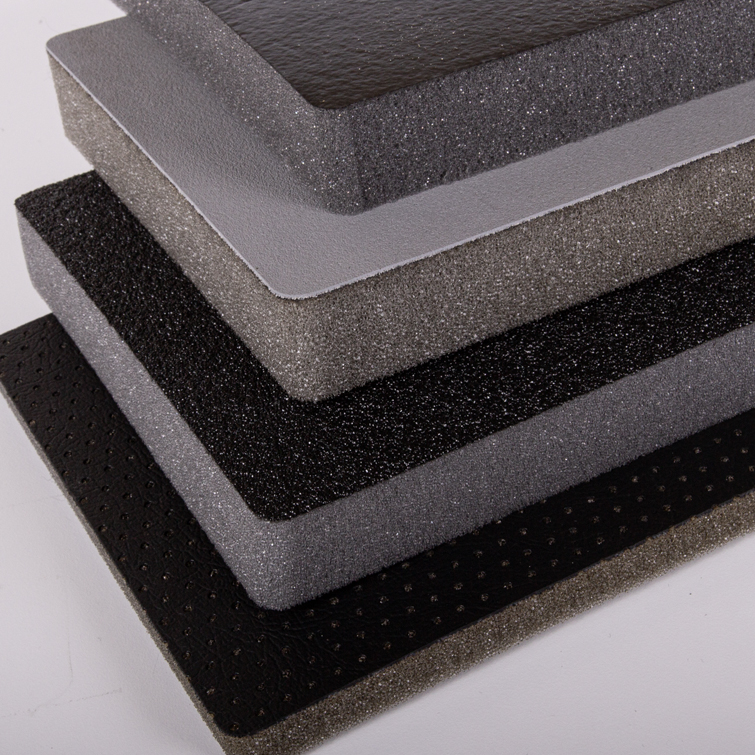

SonusTex A-87

Product summary:

SonusTex-A87 is a high temperature (200°C) rated vertically lapped synthetic fiber-based thermos-acoustic insulation material. It is engineered for higher temperature resistance for use in engine / exhaust bay applications in the automotive, commercial vehicle, industrial, bus and railcar industries. It is offered in a high performance micro-perforated, or a standard non-perforated AL foil faced version. It has improved performance and physical stability over melamine and urethane foams and fiberglass, and is a safe, non-toxic alternative to fiberglass.

Surface Density : 250 – 2000 GSM

Max. Service Temperature : Continuous: 200°C

Flammability : FMVSS302 - ≤ 100mm/min, self-extinguishing

Flammability : SAE J369 - SE/0 or better

Flammability : ASTM E162 - Flame Spread FSI 5

Flammability : ASTM E662 - Smoke Development SDI 14

Flammability : bombardier SMP 800-C - Toxicity

Flammability : UL FTSR2 - UL 2200 Certified

SonusTex A-83

Product summary:

SonusTex-A83 is suitable for automotive / commercial vehicle interiors in the following applications: behind trim, engine compartments. It is also used for insulation in the bus and railcar industries, as well as noise enclosures in industrial applications.

Surface Density : 175 – 2000 GSM

Max. Service Temperature : 150°C

Flammability : FMVSS302 - 0 mm / min., self-extinguishing

Flammability : SAE J369 - SE/0

Flammability : UL200 - Certified (ULFTSR2)

Flammability : ASTM E162 - Flame Spread FSI 5

Flammability : ASTM E662 - Smoke Development SDI 14

Flammability : Bombardier SMP 800-C - Toxicity-Compliant

SonusTex MT

Material # 96101

Product summary:

SonusTex MT polyester construction contains a densified layer on primary surface attached to a lofted substrate. This material is water-repellant, oil and fuel resistant. This acoustic material can withstand max continuous temperature of 160°C and max intermittent temperature (30 minutes) of 180°C without significant distortion, delamination or shrinkage.

Thickness : 50.4 mm construction: High density layer 1.4 ± mm, 24 ±2 mm Low density substrates: 25 ± 2 mm

Density : High density layer: 170 (kg/m³) ±10%

Density : Lower density substrate: 50 (kg/m³) ± 10%

Max. Service Temperature : Continuous (ASTM C356, 24 hr.) 160°C

Max. Service Temperature : Intermittent (ASTM C356, 30 min.) 180°C

Flammability : SAE J369 - SE/NBR

PSAs

Double Coated Acrylic Tape, Polyester Carrier

Material # 18001

Product summary:

18001 is a high strength acrylic adhesive with a polyester carrier. It provides excellent adhesion to a wide variety of substrates, including foams, plastics, foil, and low energy (LSE) plastics. It has good shear holding power at elevated temperatures. This product is suitable for fabricated foam parts bonded to contour surfaces, plastic nameplates and/or graphic overlays bonded to plastics.

Thickness : Carrier - Thickness: 0.0005” (13 µm)

Thickness : Adhesive - Thickness: 0.002” (51 µm)

Thickness : Liner - Thickness: 0.0062” (157 µm)

Service Temperature : -40°F to 250°F (-40°C to121°C)

Min. Application Temperature : 50°F (10°C)

Double Coated Acrylic Tape, Polyester Carrier

Material # 18004

Product summary:

18004 is an acrylic adhesive with a polyester carrier. It provides excellent adhesion to foams. It is water, UV, and chemical resistant. It is an ultra-low VOC (<500PPM) acrylic adhesive that exhibits a great balance of peel, tack, and shear characteristics.

Thickness : Carrier - Thickness: 0.0005” (13 µm)

Thickness : Adhesive - Thickness: 0.00125” (32 µm)

Thickness : Liner - Thickness: 0.0048” (122 µm)

Service Temperature : "-30°F to 250°F (-34°C to121°C)

Min. Application Temperature : 50°F (10°C)

Double Coated High Strength Acrylic Tape, Polyester Film Carrier

Material # 18007

Product summary:

18007 is a high strength acrylic adhesive with a polyester carrier. It provides excellent adhesion to a wide variety of substrates, including foams, plastics, foil, and low energy (LSE) plastics. It has good shear holding power at elevated temperatures. This product is suitable for fabricated foam parts bonded to contour surfaces, plastic nameplates and/or graphic overlays bonded to plastics.

Thickness : Carrier - Thickness: 0.0005” (13 µm)

Thickness : Adhesive - Thickness: 0.0034” (87 µm)

Thickness : Liner - Thickness: 0.0062” (157 µm)

Service Temperature : "-40°F to 250°F (-40°C to121°C)

Min. Application Temperature : 50°F (10°C)

Double Coated Acrylic Tape, Tissue Carrier

Material # 18300

Product summary:

18300 is designed for those foam bonding applications requiring excellent resistance to high temperature exposure. The adhesive offers good tack and adhesion with excellent shear performance. The tissue carrier offers excellent conformability to curved or irregular surfaces.

Thickness : Carrier - Thickness: 0.0022" (56 µm)

Thickness : Adhesive - Thickness: 0.0024" (61 µm)

Thickness : Liner - Thickness: 0.0046" (117 µm)

Service Temperature : Continuous: 350° F (177°C)

Service Temperature : Intermittent: 450° F (232°C)

Min. Application Temperature : 50°F (10°C)

Acrylic Transfer Tape (3 MIL)

Material # 18395

Product summary:

18395 is a high strength acrylic adhesive, suitable for bonding to most surfaces, including low energy plastics. It has good shear holding power at evaluated temperatures. This product is suitable for fabricated foam parts bonded to contour surfaces, plastic nameplates and/or graphic overlays bonded to low surface energy (LSE) plastics.

Thickness : Carrier - Thickness: 0.0062" (157 µm) or 0.0072" (183 µm)

Service Temperature : "-40°F to 250°F (-40°C to121°C)

Min. Application Temperature : 50°F (10°C)

Acrylic Transfer Tape (5 MIL)

Material # 18400

Product summary:

18400 is designed for use in applications requiring lamination to polyether and polyester urethane foams. The heavy mass of adhesive provides excellent initial tack and adhesion and should be considered for applications where a textured substrate is involved.

Thickness : Liner - Thickness: 0.0046" (117 µm)

Service Temperature : 350° F (177°C)

Min. Application Temperature : 50°F (10°C)

High Tack, Double Coated Acrylic, Tissue Carrier

Material # 18440

Product summary:

18440 is double coated version of FFT 18400, designed for those bonding applications requiring high levels of initial tack and excellent adhesion to a wide variety of materials. The tissue carrier offers excellent conformability to curved or irregular surfaces and improved dimensional stability over transfer tapes.

Thickness : Liner - Thickness: 0.0036" (91 µm)

Service Temperature : Continuous: 200°F

Service Temperature : Intermittent: 250°F

Min. Application Temperature : 50°F (10°C)

Acrylic Transfer Tape (4 MIL)

Material # 18475

Product summary:

18475 is a high strength acrylic adhesive, suitable for bonding to most surfaces, including low energy plastics. It has good shear holding power at evaluated temperatures. This product is suitable for fabricated foam parts bonded to contour surfaces, plastic nameplates and/or graphic overlays bonded to low surface energy (LSE) plastics.

Thickness : Liner - 0.0072" (183 µm)

Service Temperature : Continuous: -40°F to 200°F(-40°C - 93°C)

Service Temperature : Intermittent: -40°F to 250°F (-40°C to 121°C)

Min. Application Temperature : 50°F (10°C)

Acrylic Transfer Tape (5 MIL)

Material # 18540

Product summary:

18540 is designed for use in applications requiring lamination to polyether urethane foams. The heavy mass of adhesive provides excellent initial tack and adhesion and should be considered for applications where a textured substrate is involved.

Thickness : Liner - 0.0055" (140 µm)

Service Temperature : "-40°F to 200°F(-40°C - 93°C)

Acrylic Transfer Tape (5 MIL)

Material # 18575

Product summary:

18575 is a “high strength” acrylic adhesive with excellent flowability. It is ideally suited for bonding foam, fabrics, or other textured surfaces.

Thickness : Liner - 0.0082" (208 µm)

Service Temperature : Max Continuous: 150°F (66°C)

Service Temperature : Intermittment: -40°F to 250°F (-40°C to 121°C)

Min. Application Temperature : 50°F (10°C)

Acrylic Transfer Tape (4.5 MIL)

Material # 18700

Product summary:

18700 is designed for use in applications requiring lamination to foams, excellent initial tack and adhesion, mild plasticizer resistance, and elevated temperatures.

Thickness : Liner - 0.0043" (109 µm)

Service Temperature : Continuous: 225°F

Service Temperature : Intermittent: 300°F

Min. Application Temperature : 50°F (10°C)

![]()

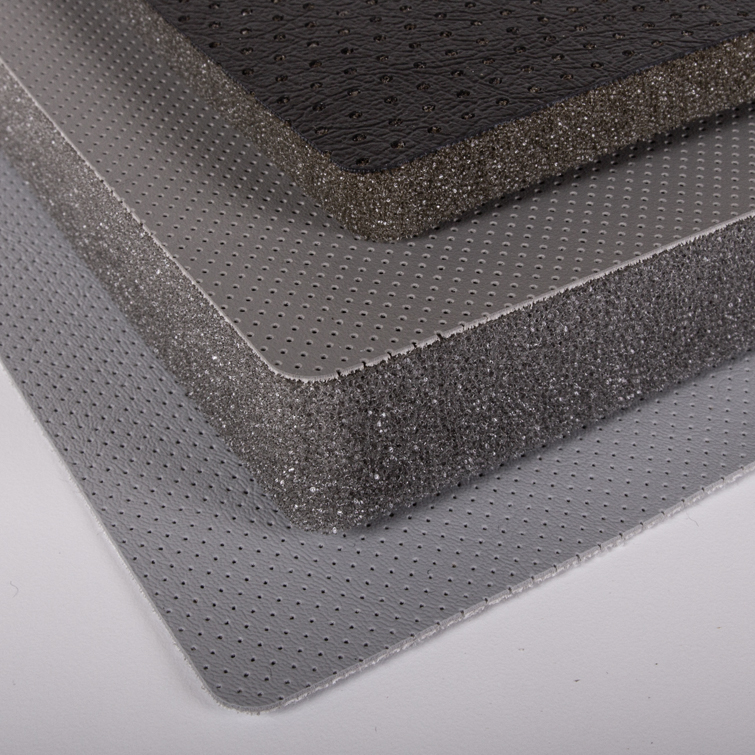

Material # 37102

Product summary:

Flame Laminated Urethane Film Flexible Polyurethane Foam

Material # 1176

Product summary:

Heat Embossed Urethane Film Flexible Polyurethane Foam

Material # 37066 , 37064

Product summary:

Flame Laminated Vinyl Flexible Polyurethane Foam

Material # 37053

Product summary:

Flame Laminated Perforated Vinyl Flexible Polyurethane Foam

Material # 37012NR

Product summary:

Moldable Flexible Vinyl Facings

Material # 21101

Product summary:

Flexible Vinyl Facings

Decorative Facing Laminates

Material # 36662

Product summary:

Moldable Needlepunch Nonwoven Felt

Material # 36601

Product summary:

Flame Laminated Moldable Needlepunch Nonwoven Felt

Product summary:

Flame Laminated Needlepunch Nonwoven Flexible Polyurethane Foam

Product summary:

Flame Laminated Spunbond Nonwoven Flexible Polyurethane Foam

Specialty

Product summary:

Moldable Fiber Glass Polypropylene Composite Sheet

Product summary:

Moldable Airlaid Polyethylene Terephthalate (PET) Sheet

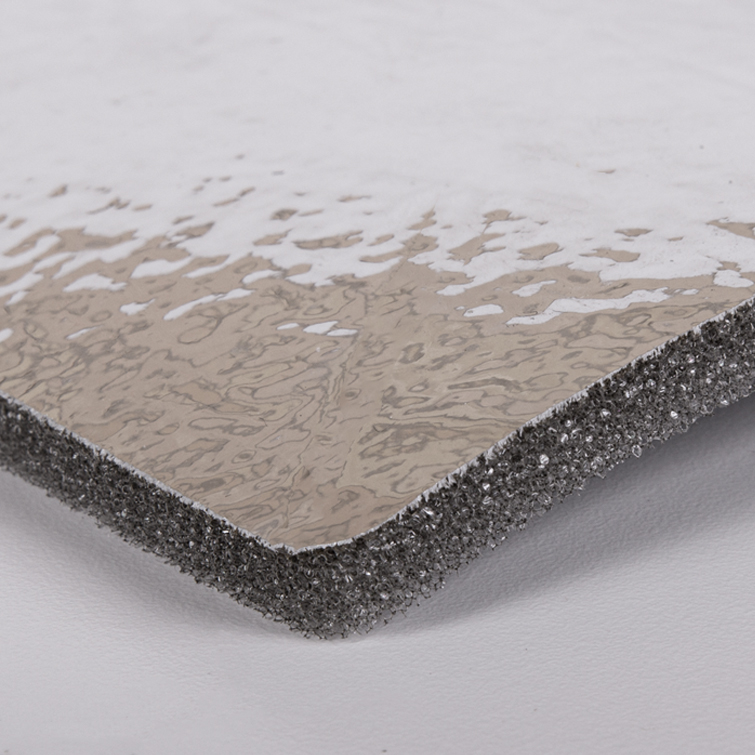

Thermal Insulators

Material # 76101

Product summary:

Reinforced Aluminum Flexible PVC Film

Material # 76100

Product summary:

Reinforced Aluminized Mylar Flexible EVA Film

Product summary:

Flame Laminated Aluminized Mylar Flexible Polyurethane Foam

Product summary:

Flame Laminated Reinforced Aluminized Mylar Flexible Polyurethane Foam